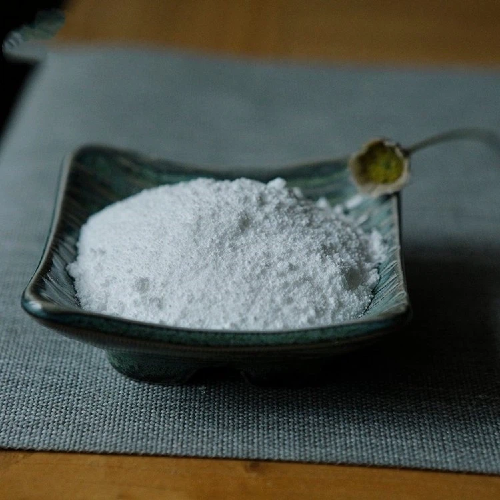

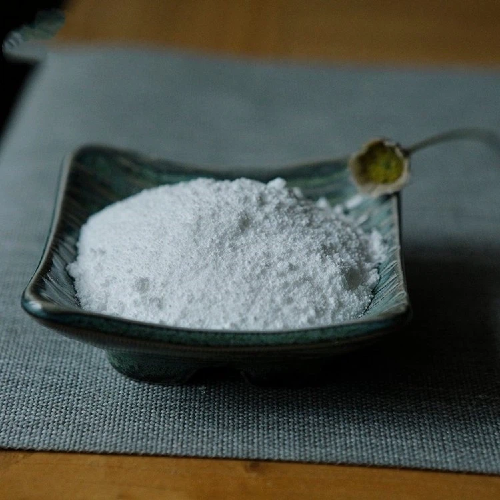

Ceramic powder is an essential material in the modern manufacturing industry, with applications in various high-performance sectors such as electronics, aerospace, and construction. The composition of ceramic powder determines its functional properties, and understanding these materials can help manufacturers optimize their processes. Jiangsu Shengtian New Materials Co., Ltd., a leading supplier of high-quality ceramic powders, is at the forefront of providing innovative solutions to meet diverse industrial needs. In this article, we will explore what ceramic powder is made of, how its composition influences its performance, and how it is processed for various applications.

1. Composition Defines Capability

The composition of ceramic powder is crucial because it directly influences the material's properties, such as its strength, durability, heat resistance, and electrical conductivity. These properties determine the powder's suitability for different applications, from industrial manufacturing to decorative arts. At Jiangsu Shengtian New Materials Co., Ltd., we focus on producing ceramic powders that meet the highest standards for a range of applications, ensuring exceptional performance in diverse industries. Understanding how the materials are combined and processed is essential for selecting the right ceramic powder for your specific needs.

2. Basic Components of Ceramic Powder

Ceramic powders are typically made from various inorganic compounds, each contributing specific properties that make the powder suitable for particular uses. The primary components of ceramic powders include:

Oxide Ceramics

Oxide ceramics, such as alumina (Al₂O₃) and zirconia (ZrO₂), are some of the most common and widely used types of ceramic powders. These materials are known for their excellent stability, high melting points, and good electrical insulating properties. Alumina is often used in applications requiring high wear resistance, while zirconia is preferred for its superior toughness and ability to withstand thermal shock. These materials are used in a variety of industrial components, including:

Electrical insulators: Used in electronic devices for insulation and thermal stability.

Wear-resistant parts: For applications in machinery and automotive components.

Non-Oxide Ceramics

Non-oxide ceramics, such as carbides (SiC) and nitrides (Si₃N₄), are commonly used when higher strength and resistance to wear and high temperatures are required. Silicon carbide, for example, is highly resistant to abrasion and is used in applications such as cutting tools, abrasives, and refractory materials. Silicon nitride, on the other hand, is known for its exceptional toughness and high-temperature resistance, making it ideal for use in:

Cutting tools: To enhance durability and precision.

Refractory materials: For furnaces and kilns, where high heat resistance is crucial.

These materials are particularly beneficial in sectors such as aerospace, automotive, and materials processing.

3. Raw Material Sources and Processing Steps

The production of ceramic powder typically begins with raw materials sourced either from natural minerals or synthesized chemically. The composition of these raw materials influences the final properties of the powder.

Mineral-Sourced vs. Chemically Synthesized Powders

Mineral-sourced powders are obtained directly from naturally occurring minerals such as bauxite (for alumina) or zircon (for zirconia). These natural materials are refined and processed to produce ceramic powders suitable for a variety of applications.

Chemically synthesized powders are produced by chemically reacting compounds in a controlled environment. This process allows for the creation of highly pure powders, often used in high-tech industries like electronics and aerospace. The ability to fine-tune the chemical composition provides manufacturers with the flexibility to create custom materials for specific applications.

Crushing, Milling, Purification, and Calcination

Once the raw materials are selected, they undergo several processing steps to turn them into high-quality ceramic powders:

Crushing and milling: Raw materials are crushed and ground into fine particles to achieve the desired particle size.

Purification: Impurities are removed to ensure that the final product is of the highest quality.

Calcination: The powder is heated to high temperatures in a kiln to improve its crystallinity and strength.

These steps are essential in ensuring the consistency and quality of ceramic powders, particularly for high-performance applications.

4. Particle Size and Purity: What They Mean

The size and purity of ceramic powders are critical factors that determine their final performance. Different applications require powders with specific particle sizes and levels of purity.

Why Particle Size Matters

The particle size of ceramic powders affects several key properties, including:

Sintering behavior: Finer particles tend to sinter more uniformly, which results in denser and stronger materials.

Density: Smaller particles can be compacted more easily, leading to higher-density materials.

Surface area: A higher surface area of the particles can improve the material's reactivity, which is particularly useful in catalytic applications.

The size of the powder is carefully controlled to meet the needs of specific applications, whether it's for high-precision parts or large-scale industrial components.

Purity Affecting Electrical, Thermal, and Mechanical Qualities

The purity of ceramic powder plays a significant role in determining its electrical, thermal, and mechanical properties. High-purity materials are typically required for applications where these properties are crucial, such as in the electronics and aerospace industries. For instance, high-purity zirconia is essential for use in electronics due to its excellent insulating properties and stability at high temperatures.

Ceramic powders with lower purity may be suitable for less demanding applications, such as construction materials, where mechanical strength and heat resistance are more important than electrical insulation.

5. How Composition Affects Application

The composition of ceramic powder has a direct impact on its performance in different applications. By tailoring the raw materials and processing steps, manufacturers can optimize ceramic powders for specific uses.

Example: High-Purity Zirconia for Electronics vs. Coarse Alumina for Refractories

High-purity zirconia is commonly used in electronics because of its excellent thermal and electrical insulating properties. It’s ideal for use in capacitors, insulators, and other electronic components that require high stability and minimal electrical conductivity.

Coarse alumina, on the other hand, is used in refractories and abrasive applications due to its high resistance to wear and thermal shock. It’s perfect for applications that involve high temperatures and mechanical stress, such as in furnaces and kilns.

The choice of ceramic material depends on the specific requirements of the application, including factors like temperature resistance, mechanical strength, and electrical conductivity.

Table: Composition → Property → Typical Use

Composition | Property | Typical Use |

Alumina (Al₂O₃) | High hardness, thermal stability | Abrasives, refractory linings |

Zirconia (ZrO₂) | High strength, thermal insulation | Electronics, fuel cells, dental ceramics |

Silicon Carbide (SiC) | Hardness, abrasion resistance | Cutting tools, abrasives, brakes |

Silicon Nitride (Si₃N₄) | Toughness, high-temperature resistance | Engine components, bearings |

This table illustrates how different ceramic powders are matched with their desired properties and applications.

6. Custom Blended Ceramic Powders Explained

While standard ceramic powders are used in a wide range of applications, many industries require custom-blended powders to meet specific performance targets. These blends are tailored based on factors such as:

Strength: For parts that need to withstand mechanical stress.

Conductivity: For applications in electrical or thermal conductivity.

Particle size and purity: To meet the specific needs of 3D printing or fine ceramics.

Jiangsu Shengtian New Materials Co., Ltd. offers custom blends of ceramic powders that are carefully designed to meet the exact specifications of each client. Whether you're looking for high-strength materials for aerospace or precise powders for medical implants, custom ceramic blends can provide the ideal solution.

Conclusion

Understanding the composition of ceramic powder is essential for selecting the right material for specific applications. By controlling the composition, particle size, and purity of ceramic powders, manufacturers can optimize their performance for a variety of industrial and decorative uses. Jiangsu Shengtian New Materials Co., Ltd. specializes in producing high-quality ceramic powders, offering precision-engineered solutions for industries such as electronics, aerospace, and construction. If you are looking for tailored ceramic materials to enhance your product performance, contact us today to explore our range of custom ceramic powders.

FAQ

What are the main components of ceramic powder?

Ceramic powder is typically made from oxides like alumina and zirconia, carbides like silicon carbide, and nitrides like silicon nitride. These materials provide unique properties for various industrial applications.

How does the particle size of ceramic powder affect its performance?

Smaller particles allow for denser and stronger materials, improving sintering behavior and surface area for better reactivity. The particle size is crucial for applications requiring precision or high-density materials.

What is the difference between mineral-sourced and chemically synthesized ceramic powders?

Mineral-sourced powders come from natural minerals like bauxite, while chemically synthesized powders are created through chemical reactions, offering higher purity and precision for high-tech applications.

Can ceramic powders be customized for specific applications?

Yes, Jiangsu Shengtian offers custom-blended ceramic powders tailored to meet specific performance targets such as strength, conductivity, and particle size for industries like aerospace and electronics.