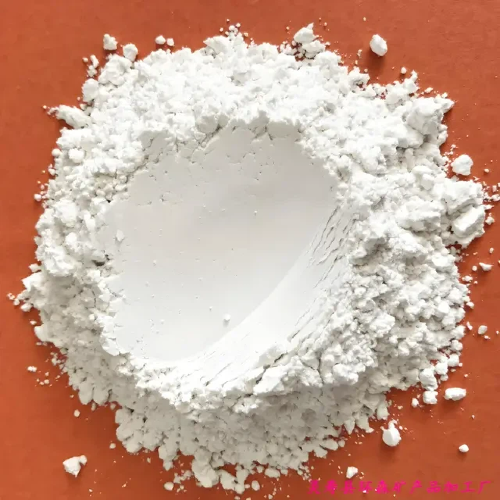

Understanding the terminology used in the materials market is crucial for both engineers and buyers. Ceramic powder is a versatile material widely used in various industries, but it is often referred to by different names depending on the context or application. As a leader in the production and supply of high-performance ceramic powder, Jiangsu Shengtian New Materials Co., Ltd. offers high-quality products that serve industries like electronics, aerospace, and construction. In this article, we’ll explore the various names for ceramic powder, why these names exist, and how the proper terminology can help buyers and engineers in their decision-making process.

1. Terminology Matters in Materials Markets

In the world of industrial materials, precise terminology is essential for ensuring clear communication between engineers, manufacturers, and buyers. Different terms for the same material can sometimes cause confusion, especially when similar substances are used for distinct applications. Ceramic powder, for example, may be referred to by various names depending on its intended use, its composition, and the industry in which it’s applied.

For ceramic powder, the term can vary from “ceramic granules” to “technical ceramic feedstock” or even “powdered ceramics” when discussing its role in additive manufacturing. These variations in terminology reflect the diverse ways that ceramic powders are utilized, whether in high-tech applications or in more traditional sectors. This article will break down the different names used for ceramic powders, provide context for when and why each is used, and show how understanding these terms can benefit buyers looking to specify the right material for their needs.

2. Common Alternative Names

Ceramic Granules, Ceramic Particulate, Technical Ceramic Feedstock

Ceramic powders are sometimes called ceramic granules or ceramic particulate. These terms emphasize the small, granular nature of the powder, particularly when it is used in bulk applications or in manufacturing processes such as casting or molding.

Ceramic granules are commonly used in industries where precise particle size is not as critical, such as in construction or some forms of refractory materials. These granules are often bulk processed and applied in various products like tiles, bricks, and sanitaryware.

Technical ceramic feedstock is a term used in more advanced applications, especially in industries like electronics, aerospace, and precision engineering. This terminology emphasizes the high-quality material that is fed into manufacturing processes such as additive manufacturing (3D printing) or sintering, where high precision and purity are essential.

Powdered Ceramics

The term powdered ceramics is commonly used when referring to ceramic materials that are used in additive manufacturing, also known as 3D printing. This term is often used to distinguish ceramic powder used for printing complex, custom-designed parts from traditional forms of ceramic powder used in bulk industrial applications.

The term powdered ceramics highlights the fine, consistent nature of the powder, which is crucial for 3D printing technologies that require smooth and uniform particle distribution to ensure precise layer-by-layer building of parts.

3. Industry Vocabulary by Application

The terminology used to describe ceramic powder varies significantly depending on the application. This variation helps clarify the intended use of the material and the specific properties it must possess.

Advanced Ceramic Feedstock

In industries like electronics, aerospace, and machinery, the term advanced ceramic feedstock is used to describe high-quality ceramic powders that are used in the creation of sophisticated components, such as capacitors, insulators, and turbine blades. The term "feedstock" here refers to the material that is fed into processes such as sintering or 3D printing to produce high-performance parts.

Advanced ceramic feedstocks often require precise control of composition and particle size to ensure the desired mechanical, electrical, and thermal properties.

Refractory Powders

Refractory powders are ceramic powders that are specifically designed to withstand extremely high temperatures without breaking down or losing their properties. These powders are commonly used in the manufacture of kiln linings, furnace linings, and other high-heat environments.

Refractory materials need to possess excellent heat resistance and durability. Terms like refractory ceramic powder or refractory particulate are often used when discussing materials used in metal processing, industrial furnaces, or the steel industry.

Pigment Powders

While less common than the other applications, pigment powders are ceramic powders used for their vibrant colors in artistic applications. These are typically used in the creation of colored glazes for pottery, tiles, or other decorative ceramic products. The use of ceramic pigments allows artists to achieve a variety of hues and textures, which are essential in the production of aesthetically appealing ceramic items.

4. Why These Different Names Exist

The variety of names used for ceramic powder can be attributed to differences in material form versus processing intent. The form of the material (granules, powders, particulates) typically reflects its size and consistency, which will influence how it is handled during production. For example, ceramic granules are larger and are typically used in bulk applications, whereas technical ceramic feedstock is often refined to ensure high purity and consistency for high-precision uses like 3D printing.

The processing intent—for instance, whether the powder is used in sintering, molding, or coating—also influences the terminology. For example:

Sintering involves heating the powder to form solid materials.

Coating involves using the powder to create a surface layer for added protection or functionality.

By distinguishing between these uses, manufacturers, engineers, and buyers can ensure they are selecting the correct material for their specific needs.

5. Examples from Real Product Catalogs

In order to understand how these terms are used in the industry, let’s take a look at how Jiangsu Shengtian New Materials Co., Ltd. markets its products. The company's product catalog uses specific terminology to highlight the applications of its ceramic powders, helping potential buyers understand the material’s uses and benefits.

Here’s a breakdown of how different names apply to ceramic powders in real product catalogs:

Product Name | Common Industry Term | Application |

Advanced Ceramic Powder | Ceramic Feedstock | Electronics, Aerospace, Automotive, 3D Printing |

Refractory Ceramic Powder | Refractory Powders | High-Temperature Manufacturing, Metal Processing |

Decorative Ceramic Pigment | Pigment Powders | Pottery, Tiles, Art, Ceramics |

Custom Blended Ceramic Powders | Custom Ceramic Feedstock | Tailored for Specific Requirements (Strength, Conductivity) |

These names help clarify the intended use of each ceramic powder, ensuring that the correct material is chosen for the right application.

6. How Knowing These Terms Helps Buyers

For buyers, understanding the different names and terms for ceramic powder is essential in ensuring they select the right material for their specific application. Here’s how knowing these terms can help:

Improved Search Results: By using the correct industry terminology, buyers can find the right material more quickly through search engines, improving their ability to source specific products.

Specification Matching: Understanding terms like “advanced ceramic feedstock” or “refractory powders” ensures that buyers match the material’s specifications to their project needs.

Better Supplier Communication: Clear communication with suppliers is vital for ensuring the right material is sourced. Knowing the correct terms allows buyers to precisely describe their requirements, which helps avoid misunderstandings.

By using industry-standard terminology, buyers can streamline the procurement process, ensuring they get the right material with the properties they need.

Conclusion

The terminology surrounding ceramic powder plays a significant role in understanding its various uses and applications. Whether referred to as ceramic granules, technical ceramic feedstock, or powdered ceramics, the name used typically reflects the powder’s intended application and the industry in which it is utilized. Jiangsu Shengtian New Materials Co., Ltd. offers high-quality ceramic powders tailored for a variety of industries, from advanced ceramics in electronics and aerospace to decorative ceramics for artistic applications. If you need precise, high-performance ceramic powders for your next project, contact us today to learn more about our products.

FAQ

What is the difference between ceramic granules and ceramic feedstock?

Ceramic granules are typically larger and used in bulk applications, while ceramic feedstock refers to high-purity powders used in advanced manufacturing processes like 3D printing.

Can ceramic powders be used in 3D printing?

Yes, ceramic powders specifically designed for additive manufacturing can be used in 3D printing to produce complex parts with high precision.

What industries use refractory ceramic powders?

Refractory ceramic powders are used in industries that require heat-resistant materials, such as metal processing, aerospace, and furnace manufacturing.

What is the best ceramic powder for decorative ceramics?

Decorative ceramic pigments are the best option for achieving vibrant colors and textures in pottery, tiles, and other artistic ceramic creations.