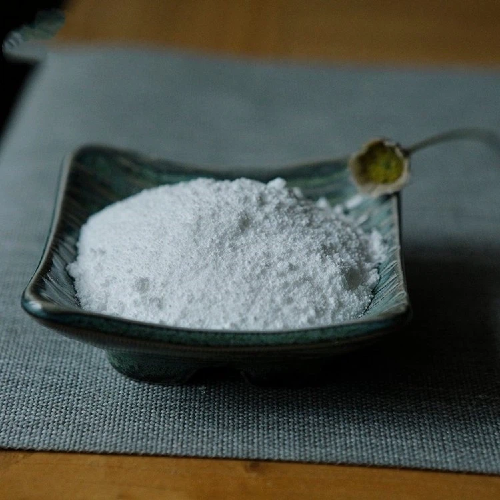

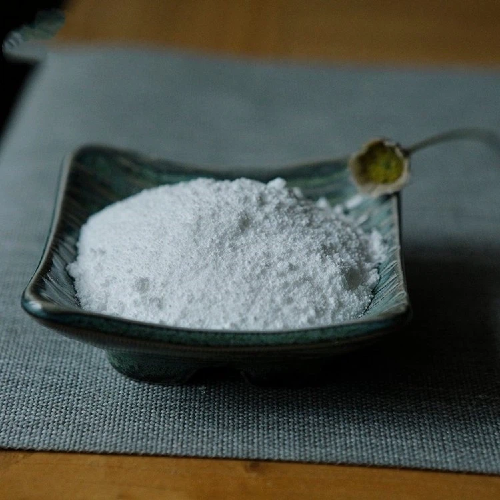

When it comes to choosing industrial materials, safety is always a top priority. One of the most common questions that buyers have before purchasing materials like ceramic powder is whether the material is flammable. Whether you're working with ceramic materials in manufacturing, 3D printing, or any other application, understanding the flammability and handling requirements of the material is crucial for ensuring safe operations. As a leading producer of high-quality ceramic powders, Jiangsu Shengtian New Materials Co., Ltd. provides comprehensive safety guidelines and products designed to meet the highest industry standards. In this article, we will delve into the flammability of ceramic powder, the risks associated with its dust, and the best safety practices to follow when handling and storing these materials.

1. Why Safety Knowledge Is Critical

For many buyers and manufacturers, understanding the flammability of materials like ceramic powder is critical to ensuring a safe working environment. Many people search for this information before purchasing ceramic materials, as safety regulations in industrial settings are strict, and mishandling materials can lead to accidents or damage. As ceramic powder is often used in high-performance applications, such as electronics, aerospace, and manufacturing, it is essential to know how to handle it safely.

In this article, we’ll explain why ceramic powders are typically non-flammable, discuss the potential risks associated with powder dust, and provide practical safety guidelines for handling and storing these materials. By understanding these important facts, you’ll be equipped to make informed decisions and maintain a safe working environment.

2. Inherent Non-Flammability of Ceramic Materials

Ceramic powders are inherently non-flammable and chemically stable, which is one of the reasons why they are widely used in high-performance applications. The materials used in ceramic powders, such as oxides, carbides, and nitrides, are typically stable at extremely high temperatures. This makes them ideal for use in industries where heat resistance and fire safety are paramount.

For example, materials like alumina (Al₂O₃) and zirconia (ZrO₂) are both chemically stable and resistant to combustion, meaning they will not ignite or contribute to the spread of fire. The properties of ceramic powders make them essential in industries like aerospace, automotive, and electronics, where high thermal stability and flame resistance are necessary.

Moreover, the production processes used to create ceramic powders, such as sintering and calcination, involve heating the raw materials to extremely high temperatures, which further demonstrates the materials' ability to withstand high heat without breaking down or becoming flammable.

3. Dust Risks vs. Material Flammability

While ceramic powders themselves are non-flammable, it’s important to consider the risks associated with dust clouds generated by powdered materials in industrial settings. Ceramic powder dust can pose a physical hazard if not properly controlled, and while the powder itself is not flammable, the dust may be combustible under certain conditions.

In general, powdered materials can form explosive dust clouds when suspended in air, especially in confined spaces or areas without adequate ventilation. If a spark or ignition source is present, these dust clouds can ignite, leading to a dust explosion. Therefore, it’s essential to handle ceramic powders with care to avoid generating dust clouds and to follow proper safety protocols to minimize any risk of combustion.

Key steps to reduce dust risks include:

Using proper ventilation systems to prevent dust from accumulating in the air.

Implementing dust collection systems to capture any airborne particles.

Avoiding static buildup by using grounded equipment and wearing proper grounding straps.

While the powder itself is non-flammable, ensuring that dust is kept under control is a crucial safety measure.

4. Safety Data Sheet (SDS) Insights

One of the most valuable resources for understanding the safety requirements of ceramic powder is the Safety Data Sheet (SDS). The SDS provides detailed information on the material’s composition, hazards, handling guidelines, and safety precautions.

For ceramic powder, the SDS will typically indicate the following:

Non-flammability: As stated earlier, ceramic powders are non-flammable under normal conditions, meaning they will not ignite or combust without extreme heat.

Handling and Storage: The SDS will provide storage conditions for ceramic powders, which generally include keeping the material dry and avoiding exposure to moisture. It will also include recommendations for handling, such as using personal protective equipment (PPE) like gloves, goggles, and respiratory protection when working with ceramic powders to avoid inhalation of dust.

Exposure Limits: While the powder itself is not hazardous, long-term exposure to dust can pose respiratory risks. The SDS will detail acceptable exposure limits and recommended exposure controls to ensure safe working conditions.

By referring to the SDS for ceramic powders, manufacturers and users can ensure they are following the correct safety procedures and maintaining a safe working environment.

5. Practical Handling and Storage Tips

Even though ceramic powder is non-flammable, proper handling and storage are essential to maintain safety and prevent accidents. Here are some best practices to follow:

Avoid Dust Clouds

Keep dry: Moisture can cause ceramic powders to clump together, making them more difficult to handle and increasing the risk of generating dust.

Use appropriate containers: Store ceramic powder in sealed, airtight containers to prevent dust from escaping into the air.

Minimize handling: Limit the handling of the material to prevent excessive dust generation.

Personal Protective Equipment (PPE)

When handling ceramic powders, it is crucial to use appropriate PPE:

Respirators: To prevent inhalation of fine dust particles, use a properly fitted respirator with a particulate filter.

Gloves: To avoid direct contact with the material and protect your hands.

Eye protection: Safety goggles or face shields should be worn to protect the eyes from airborne dust.

Ventilation and Dust Collection

Ensure that the workspace is well-ventilated to prevent the accumulation of dust in the air. Using exhaust systems and dust collectors can help reduce airborne dust.

Install air filtration systems to capture and filter dust particles, ensuring clean air and a safer working environment.

6. When Special Precautions Are Needed

While ceramic powders are generally safe to handle, special precautions may be necessary when they are co-formulated with other materials or mixed with binders. When ceramic powders are combined with other substances, the resulting mixture could have different properties, such as increased flammability or reactivity.

For example:

Binder-based ceramic powders: Some ceramic powders are mixed with binders for use in applications such as 3D printing. If the binder material is flammable, additional precautions must be taken to handle the mixture safely.

Co-formulated powders: In some cases, ceramic powders may be combined with other chemicals or materials for specialized applications. Understanding the composition of the mixture and its potential hazards is crucial for safe handling.

In these cases, the Safety Data Sheet will provide specific guidance on the safety measures needed for the specific formulation.

Conclusion

Ceramic powder is inherently non-flammable and chemically stable under normal conditions, making it a safe material to work with in a variety of industrial applications. However, the dust produced by ceramic powders can pose a risk in certain environments, especially if proper safety measures are not in place. By understanding the risks and taking appropriate precautions, such as controlling dust, using personal protective equipment (PPE), and following Safety Data Sheet (SDS) guidelines, workers can safely handle ceramic powder without incident. Jiangsu Shengtian New Materials Co., Ltd. provides high-quality ceramic powders that meet the highest safety standards for use in industries such as electronics, aerospace, and construction. If you need reliable, high-performance ceramic materials for your projects, contact us today to learn more about our products and ensure safe, efficient operations.

FAQ

Is ceramic powder flammable?

No, ceramic powder is non-flammable and chemically stable under normal conditions.

What are the risks associated with ceramic powder dust?

The main risk comes from dust clouds, which can pose an explosion hazard in industrial environments. Proper dust control and ventilation are essential.

What precautions should I take when handling ceramic powder?

Always use appropriate PPE, such as gloves, goggles, and respiratory protection, and ensure proper ventilation and dust control.

Do ceramic powders require special handling when combined with binders?

Yes, when ceramic powders are mixed with binders or other chemicals, additional precautions may be necessary, as the resulting mixture may have different properties.